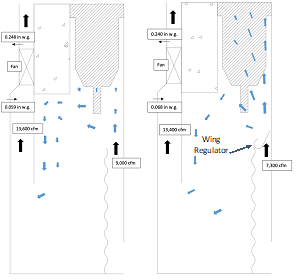

Summary: Mining operations work to provide fresh air to the miners and machines developing the underground workings. In an underground room-and-pillar coal mine section, the fresh air is intended to sweep the front of the continuous mining machine to dilute pollutants, such as methane and dust that are produced as a consequence of excavation. Many of these mines employ a blowing face ventilation scheme where a line curtain, placed on the opposite side of continuous miner’s scrubber discharge, is used to direct the fresh air to the face. In deep cuts where the continuous miner advances the face up to 40 feet beyond the last row of permanent supports, the fresh air does not have sufficient velocity to reach the face and instead takes a low resistance path to the return portion of the airway. As a result, methane and dust concentrations could build up at the face, causing significant health and safety related issues in the mine.

The University of Kentucky developed a Wing Regulator for improved face ventilation on extended cuts. The Wing Regulator showed improvement in all monitored ventilation parameters, including the air flow velocities at the face, gas concentration at the face, dust concentration at the CM’s operator zone. Gas concentrations at the face were reduced by more than 40% when the Wing Regulator was employed. It was also demonstrated t that the scrubber can cleanse the additional dust that was removed from the face by the Wing Regulator.